Lighting modernization

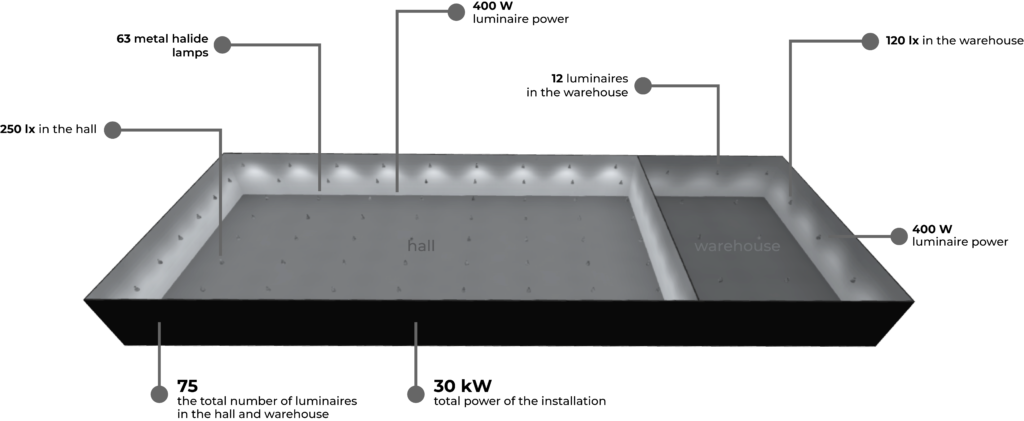

The company X has a production hall with an area of 2,500 m2 and a warehouse with an area of 900 m2. The entire facility is 8 m high and equipped with 400 W metal halide lamps.

Step 1: Assessment of the actual state

Step 2: Analysis

At this stage, we calculate the cost of using the lighting, evaluate the profitability of modernization, propose an appropriate luminaire and prepare a lighting design tailored to the facility.

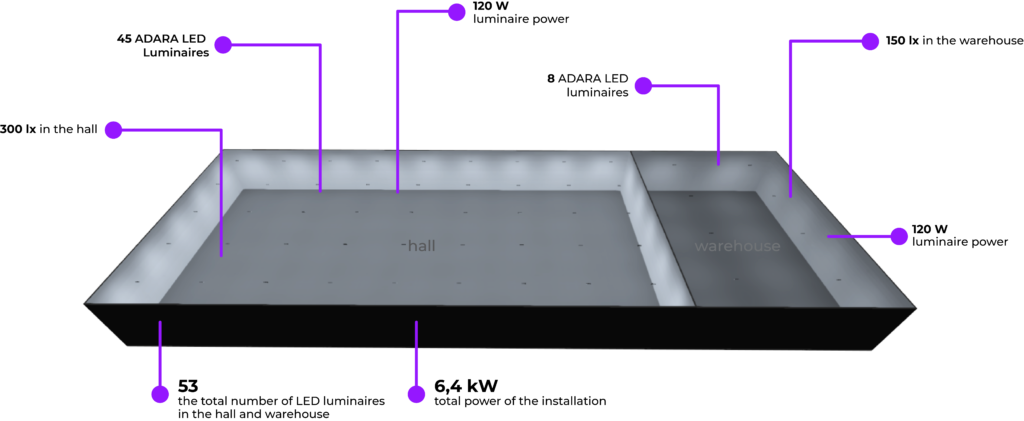

The production plant after modernization

Step 3: Implementation

| Type | Luminaire power | Quantity | Lighting installation power | Annual electricity consumption |

|---|---|---|---|---|

| Metal halide lighting | 400 W | 75 | 30 kW | 262 800 kWh |

| Bilberry LED lighting | 120 W | 53 | 6,4 kW | 55 714 kWh |

Step 4: Usage

After modernization, we will perform measurements of lighting and electrical installations and provide full post-implementation documentation. The long lifespan of the luminaires and a long warranty will allow for trouble-free use of lighting for many years, even in the toughest industrial conditions. No need to periodically replace burnt-out light sources is an additional saving of money and time.